Business Assurance Services (BAS)

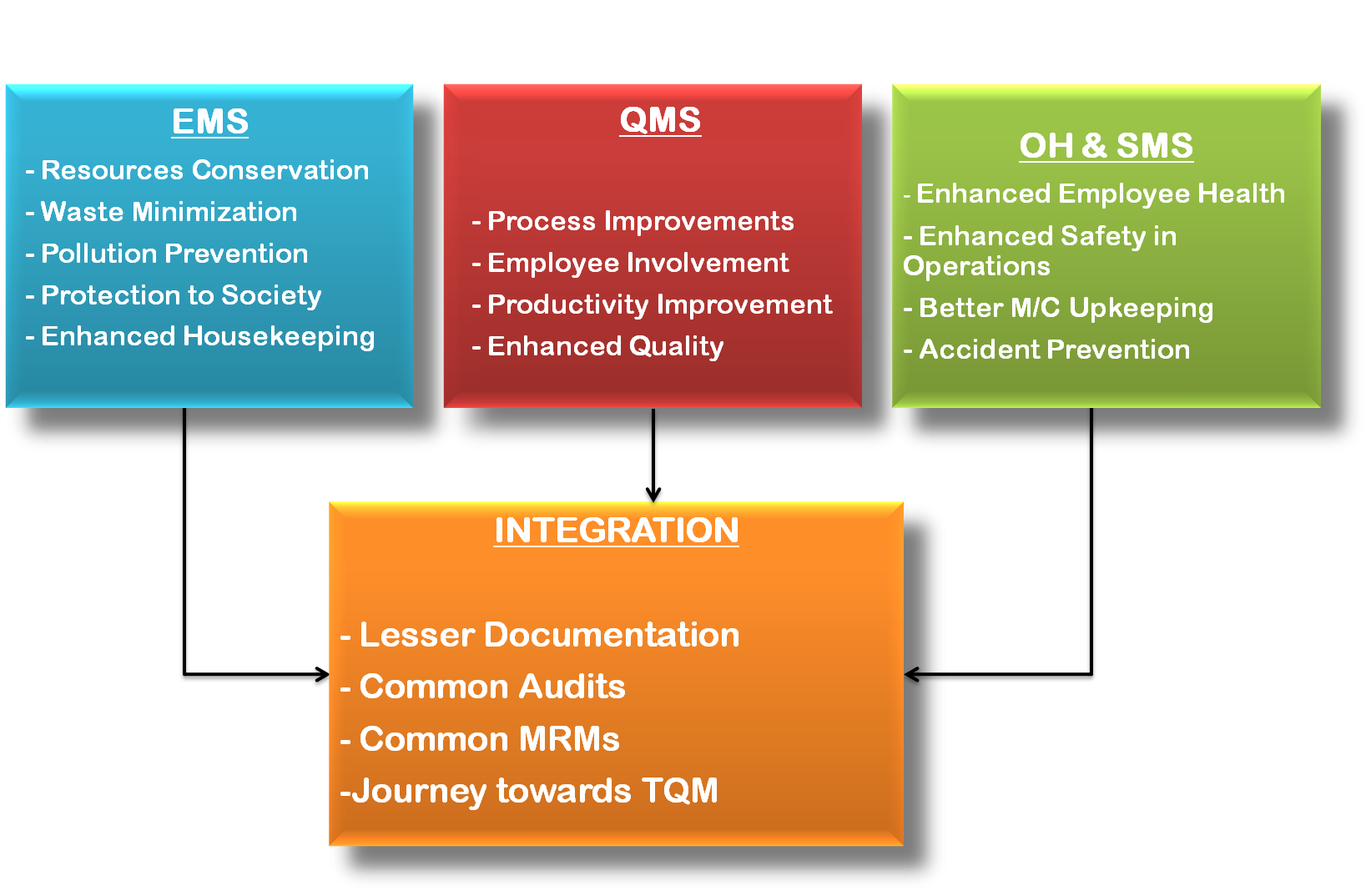

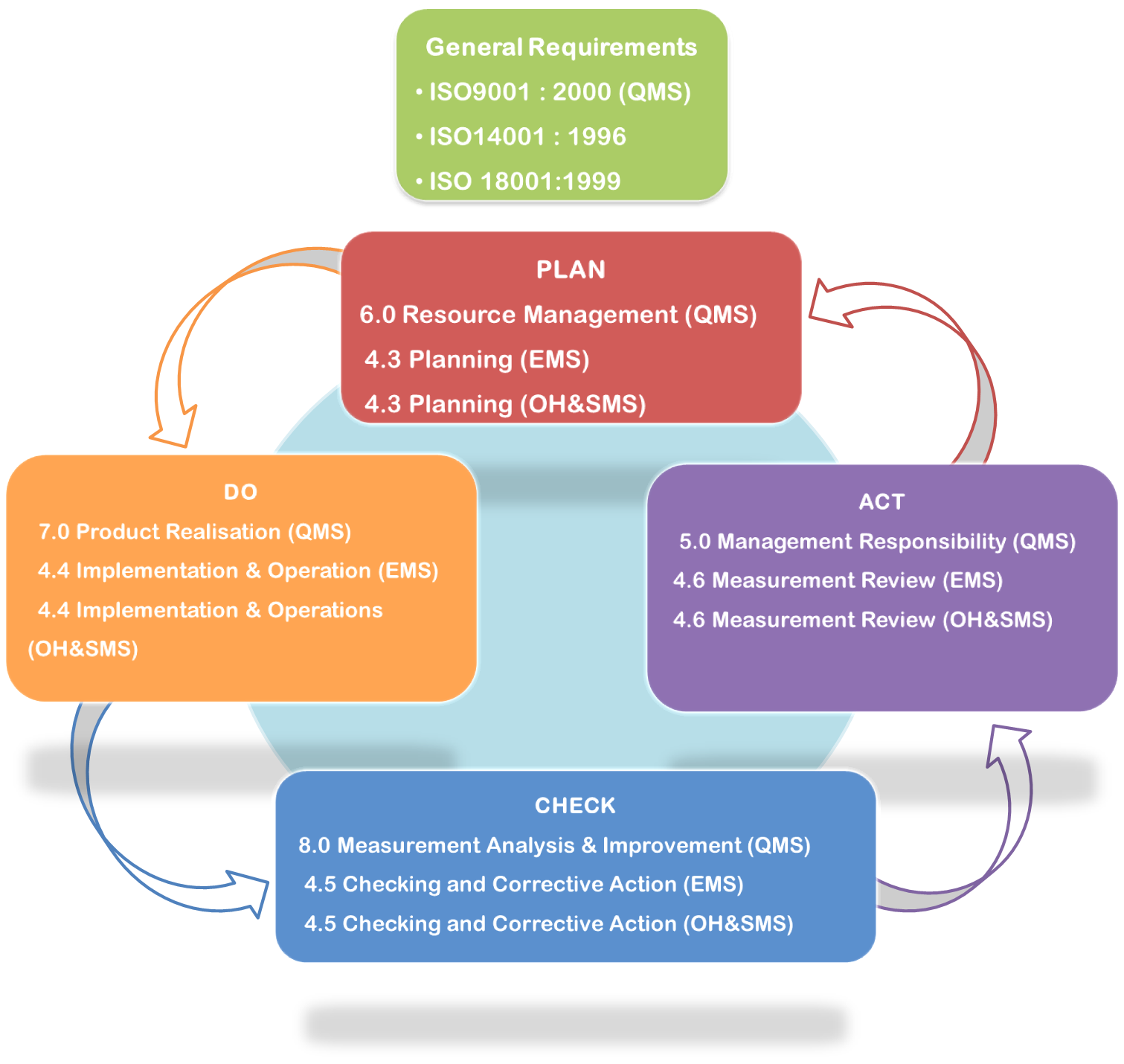

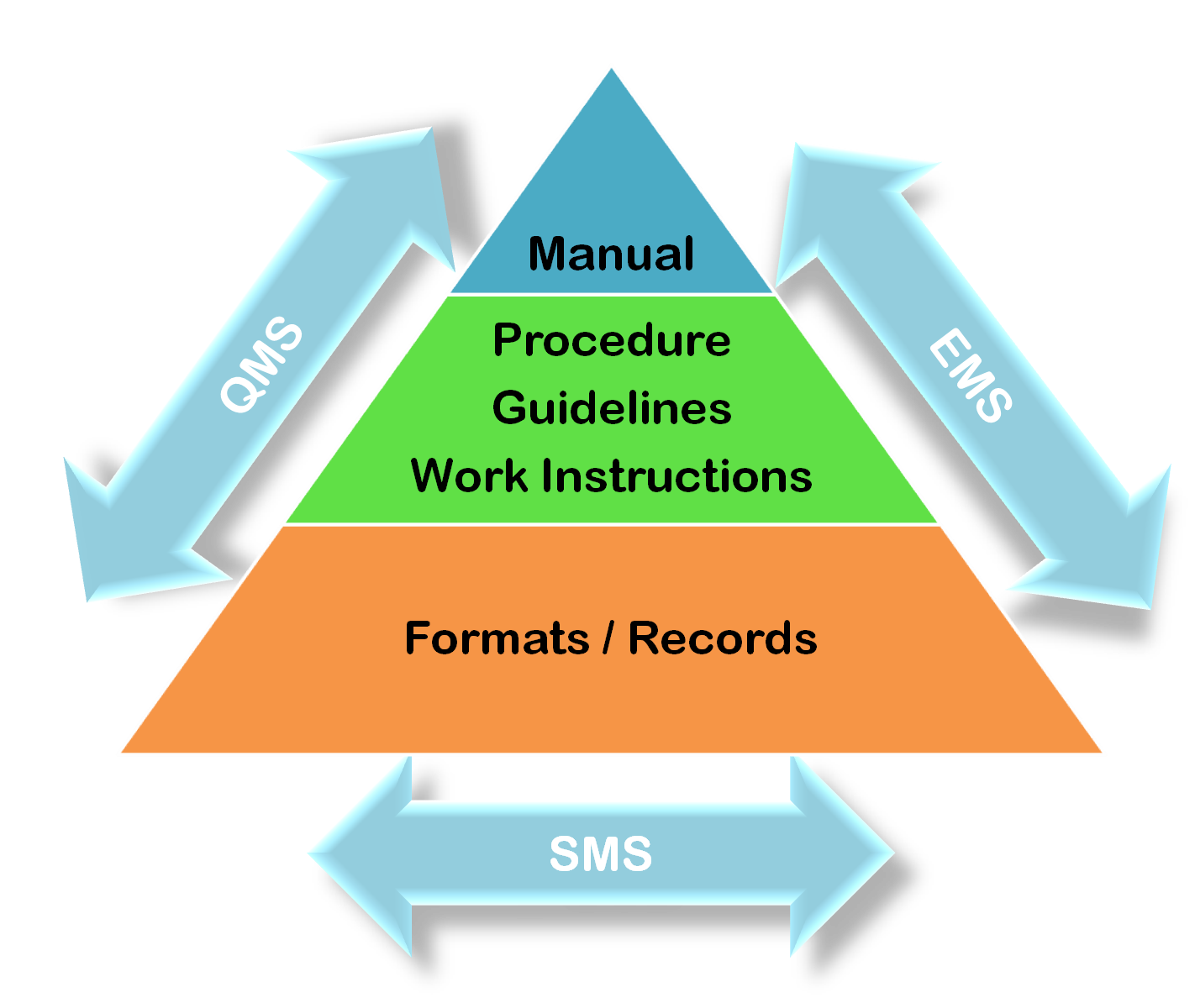

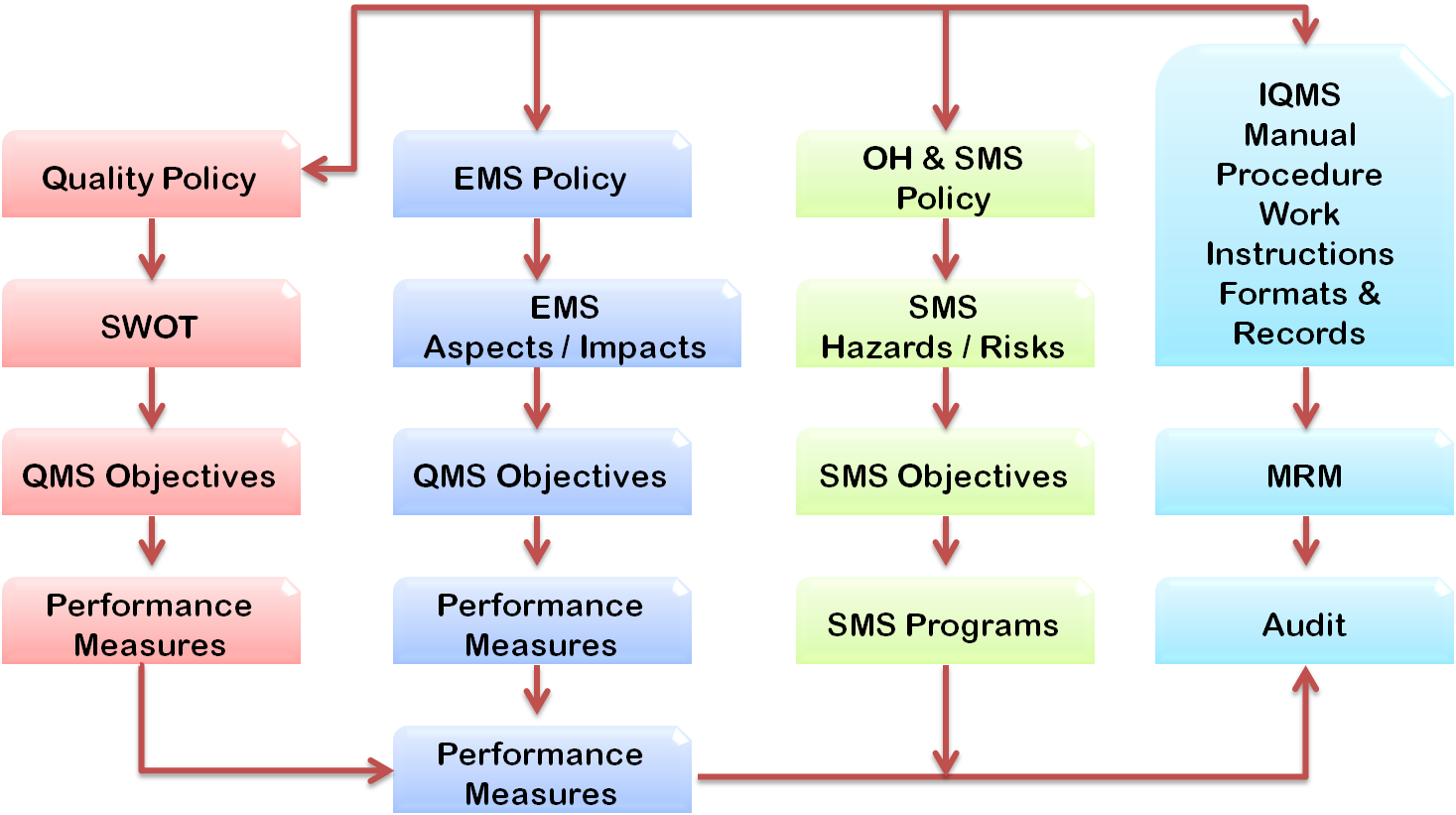

We also have developed a unique Integrated Quality Management System , covering ISO 9001:2015 , ISO 14001:2015 , ISO 45001:2018 with single documentation ,Audit and certification , the first time in India.

ISO 14001:2015 Certification

ISO 45001:2018 Certification

TS 16949 (IATF 16949 : 2016) Certification

ISO 22001:2005 Certification

ISO 27001:2013 Certification

ISO 50000 : 2011 certification

SA 8000:2014 Certification

IMS

Bench Marking

Business Assurance Services - ISO 9001:2015

In todays business compliance regulations, a certified Quality Management System (QMS) based on ISO 9001:2015 standards is almost a minimum requirement. URS productively has helped hundreds of companies since 1995 , in establishing QMS , obtaining the certification. The unique approach of URS here is to ensure that the QMS system is integrated with management control requirements and the organization gets business value from the system as well.

Benefits Of ISO 9001

External Benefits From the View Point Of the Customer

Increased Customer Confidence

Increased market

Preferred supplier status

Many Indian and Overseas customer now suggest that their key suppliers are ISO certified

Internal Benefits From the View Point Of the Company

Well Documented Systems

Less Rejections and Quality Cost

Improved Productivity

Continuous Improvement

Starting Platform for concepts like BPR and TQM

URS Values

Our Basic Value in ISO 9001 implementation is to provide our clients much more than the certification. To achieve this we focus on improvement of systems rather than simply meeting the requirements of the standard. We ensure integration of ISO 9000 systems with business improvement.

METHODOLOGY

ST1 PREPARATORY STAGE

ST11 Vision,Mission, Policies and Business Plan in line with context of Organization

ST12 Induction of Stake Holders

ST13 Top Management Training

ST2 SYSTEM DEVELOPMENT STAGE:

ST21 System Study

ST22 Identification of system gaps

ST23 Development of New Systems / Processes

ST24 Risk Analysis

ST25 Management Plans

ST26 Objectives and Performance Measures

ST27 Organization Structure

ST3 SYSTEM IMPLEMENTATION:

ST31 Documented Information on SOPs

ST32 Documented Information on Processes

ST33Documented Information Templates and Formats

ST34Implementation Support Training at all levels

ST35Training on Internal Audit

ST4 INTERNAL AUDIT AND CORRECTIVE ACTIONS

ST41 Internal Audit

ST42 Management Review

ST5 Stage I audit (Readiness Review)

ST6 CERTIFICATION AUDIT

Business Assurance Services - ISO 14001:2015

Compliance to certify Environment Management System (EMS) based on ISO 14001:2015 makes business sense as this standard helps in controlling the waste , and also unproductive time loss in litigations. URS productively has helped several organizations since 2000 , in establishing EMS , obtaining the certification. The unique approach of URS here is to ensure that the EMS system is integrated with management control requirements and the organization gets business value from the system as well.

Benefits Of ISO 14001

External Benefits From the View Point Of the Customer

Threats from society, government on environmental issues are minimized.

Trade barrier from certain customers is avoided.

The unproductive time loss in litigation is avoided.

Certain solutions for EMS may increase productivity.

Since lesser the input, lesser the pollution, efforts to minimize inputs is under taken.

Reprocessing is controlled.

Waste minimization

Energy and water conservation

Objective

Our Basic Value in ISO 14001 implementation is to introduce an EMS system that results in input saving for organization, Process Optimization and Energy Efficiency.

Approach

Process survey identifying the waste / emission sources , type and severity will be conducted , covering all the activities of the company. Risk evaluation will be performed to prioritize the environmental aspects. Environment Management Programs (EMPs) will be drafted based on the aspects , environmental policy of the company. Mechanism for monitoring the implementation will be introduced. Environment Management Documentation will be prepared covering all these issues. A software is provided for monitoring objectives , targets , action plans.

METHODOLOGY

ST1 PREPARATORY STAGE

ST11 Vision,Mission, Policies and Business Plan in line with context of Organization

ST12 Induction of Stake Holders (Legal Requirements /Gap Analysis and Action planning)

ST13 Top Management Training

ST2 SYSTEM DEVELOPMENT STAGE:

ST21 System Study

ST22 Identification of system gaps

ST23 Development of New Systems / Processes / Response to Emergency

ST24 Risk Analysis, Identification of Environmental Aspects

ST25 Objectives, Management Programs , Controls

ST26 Performance Measures

ST27 Organization Structure

ST3 SYSTEM IMPLEMENTATION:

ST31 Documented Information on SOPs

ST32 Documented Information on Processes

ST33Documented Information Templates and Formats

ST34Implementation Support Training at all levels

ST35Training on Internal Audit

ST4 INTERNAL AUDIT AND CORRECTIVE ACTIONS

ST41 Internal Audit

ST42 Management Review

ST5 Stage I audit (Readiness Review)

ST6 CERTIFICATION AUDIT

Business Assurance Services - ISO 45001:2018

Compliance to certify Safety Management System (SMS) based on ISO 45001:2018 makes business sense as this standard helps in controlling the production losses due to incidents and accidents, and time loss in litigations as well. URS productively has helped several organizations since 2000, in establishing SMS , obtaining the certification. The unique approach of URS here is to ensure that the SMS system is integrated with management control requirements and the organization gets business value from the system as well.

Benefits Of ISO 45001:2018:

Enhanced employee health

Enhanced Safety in Operations

Better UP- keeping Of Machines

Accident prevention

URS Values

Our Basic Value in ISO 45001:2018 implementation is to introduce a SMS system that results in safe work practices , safe working conditions and better equipment maintenance

Approach:

Process survey identifying the safety hazards/ risks , type and severity will be conducted , covering all the activities of the company. Risk evaluation will be performed to prioritize the safety hazards. Safety Management Programs (SMPs) will be drafted based on the safety hazards , Safety policy of the company. Mechanism for monitoring the implementation will be introduced. Safety Management Documentation will be prepared covering all these issues. A software is provided for monitoring objectives, targets, action plans.

METHODOLOGY

ST1 PREPARATORY STAGE

ST11 Vision,Mission, Policies and Business Plan

ST12 Induction of Stake Holders(Legal Requirements /Gap Analysis and Action planning)

ST13 Top Management Training

ST2 SYSTEM DEVELOPMENT STAGE:

ST21 System Study

ST22 Identification of system gaps

ST23 Development of New Systems / Processes / Response to Emergency

ST24 Risk Analysis, Identification of Safety Hazards

ST25 Objectives, Management Programs, Controls

ST26 Performance Measures

ST27 Organization Structure

ST3 SYSTEM IMPLEMENTATION:

ST31 Documented Information on SOPs

ST32 Documented Information on Processes

ST33Documented Information Templates and Formats

ST34Implementation Support Training at all levels

ST35Training on Internal Audit

ST4 INTERNAL AUDIT AND CORRECTIVE ACTIONS

ST41 Internal Audit

ST42 Management Review

ST5 Stage I audit (Readiness Review)

ST6 CERTIFICATION AUDIT

Business Assurance Services - TS 16949 (IATF 16949 : 2016)

The Need:

IATF 16949 : 2016 is an Quality Management System standard for automotive production and relevant service part organizations. This standard has to be considered in conjunction with ISO 9001: 2015 and customer specific requirements for the automotive supply chain to conform to the Automotive Quality Management system adopted by OEMs.

Benefits Of IATF 16949 : 2016

Enhanced Corporate Image (External)

Lean Practices such as Kaizen, 5S, SQC, SPC15:35 17/02/2017, FMEA

Implementation of Performance Measures

Identification of Process Non Conformity Analysis and Control

Improvement of Process Quality

Improvement of Process Throughput Time

Possible Reduction in Process Cost

Continuous Improvement

URS Values

Our Basic Value in Of IATF 16949 : 2016implementation is to introduce a Automotive Quality Management , with powerful process improvement tools to make the organization TQM ready.

Approach:

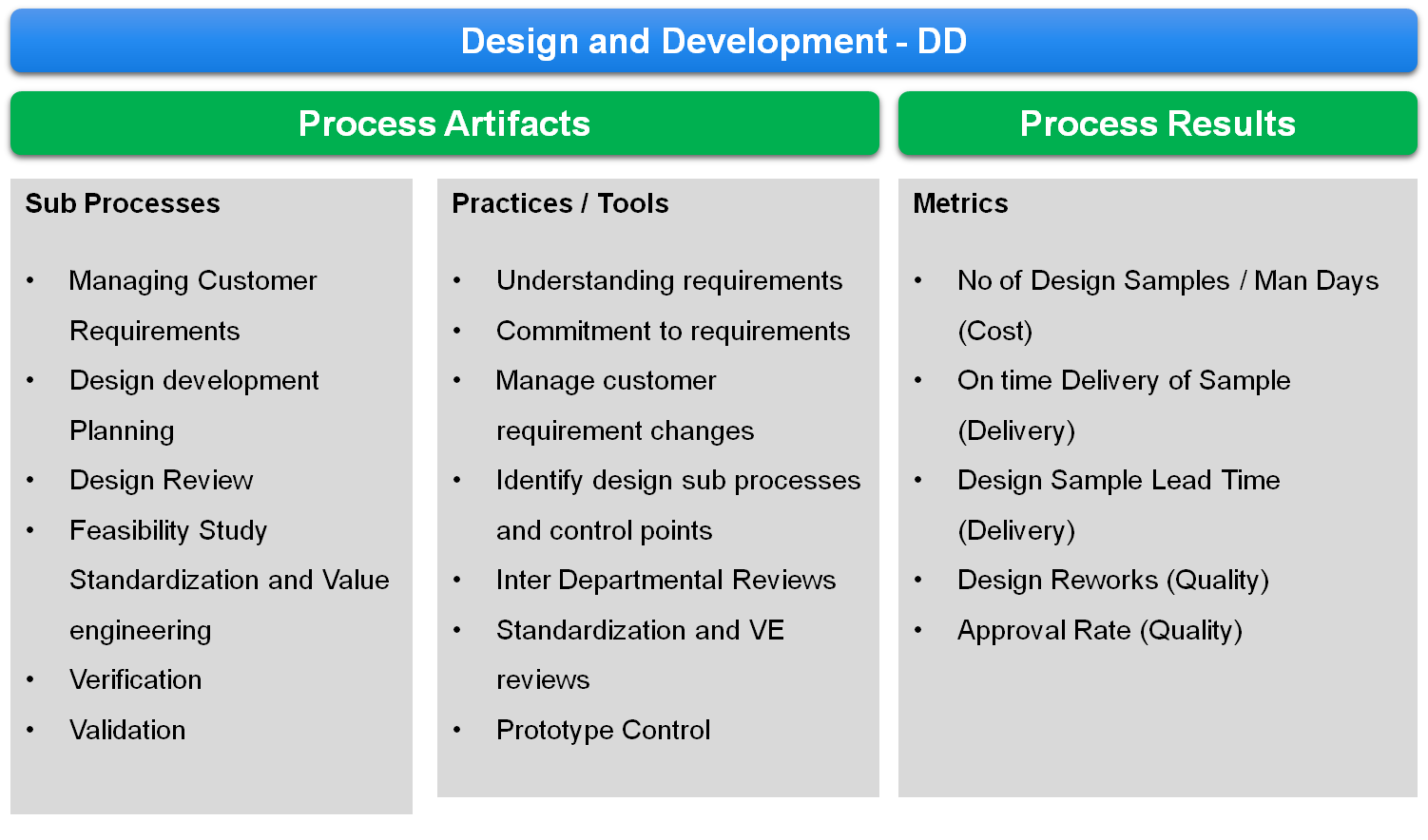

A Process oriented approach with controls on input, Process, Output framework will be used besides stream lining the process artifacts namely the tools. The tools will encompass tools for control tools for analysis and improvement. Process wise metrics will be inherent part of the process.

METHODOLOGY

ST1 PREPARATORY STAGE

ST11 Vision,Mission, Policies and Business Plan

ST12 Induction of Stake Holders(Legal Requirements /Gap Analysis and Action planning)

ST13 Top Management Training

ST2 SYSTEM DEVELOPMENT STAGE:

ST21 System Study

ST22 Identification of system gaps

ST23 Development of New Systems / Processes / Process Metrics

ST24 Core Tools - APQP , PPAP , FMEA , SPC , MSA

ST25 Objectives, Management Programs, Controls

ST26 Performance Measures

ST27 Organization Structure

ST3 SYSTEM IMPLEMENTATION:

ST31 Documented Information on SOPs

ST32 Documented Information on Processes

ST33Documented Information Templates and Formats

ST34Implementation Support Training at all levels

ST35 Training on Process Improvement Tools 5S , Kaizen

ST36 Training on Internal Audit

ST4 INTERNAL AUDIT AND CORRECTIVE ACTIONS

ST41 Internal Audit

ST42 Management Review

ST5 Stage I audit (Readiness Review)

ST6 CERTIFICATION AUDIT